Resonance In A Nuclear Charge Pump Natural Frequency

Resonance In A Nuclear Charge Pump Natural Frequency: A nuclear power plant encountered a sudden high vibration problem with one of two motor driven charge pumps. The plant decided to have MSI perform specialized testing and analysis to determine the problem root cause and a solution rather than tearing down the pump for inspection.

- Problem Statement (Challenge)

- What (type of machine): Charge Pump in a Nuclear Power Plant

- Where (State/ Country): Northeast USA

- Why (problem/reason): Plant personnel suspected a shaft crack. The motor power tripped during operation but the motor restarted as the pump was coasting down. Vibration amplitude increased significantly (accelerometer measurement of about 0.05 ips peak increased to 0.22 ips peak at 1 x pump running speed of 4812 rpm on the outboard bearing housing in the horizontal direction). Also erratic shaft vibration amplitude and phase angle.

- Work Performed

- Results/ Solution

- Findings: The problem source was a downward shift in a lightly damped structural natural frequency to within 5% of running speed creating a resonant (high vibration) condition at the outboard bearing housing.

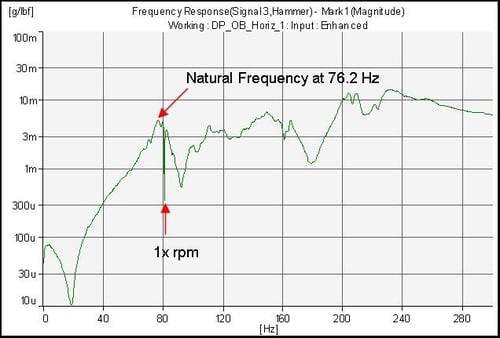

Time Averaged Pulse (TAP) experimental modal analysis (impact) test results show the structural natural frequency with 5% of running speed (i.e., resonant condition causing the high vibration).

Time Averaged Pulse (TAP) experimental modal analysis (impact) test results show the structural natural frequency with 5% of running speed (i.e., resonant condition causing the high vibration).

The ODS test results revealed why the resonant high vibration condition was erratic – there was a soft foot condition at the outboard end of the pump. Soft foot conditions can produce an erratic vibration pattern due to non-linear or variable “soft foot” contact.

ODS animation showing looseness between the pump and its pedestal.

It seemed reasonable that the electric power loss situation led to the soft foot.

-

- Solution: Torque inboard and outboard casing to pedestal bolts to correct values.

The customer questioned the simplicity of the solution. Therefore, MSI used FEA to demonstrate that looseness at the outboard pump feet did result in a drop of the structural natural frequency to near 1 times running speed creating a resonant condition.

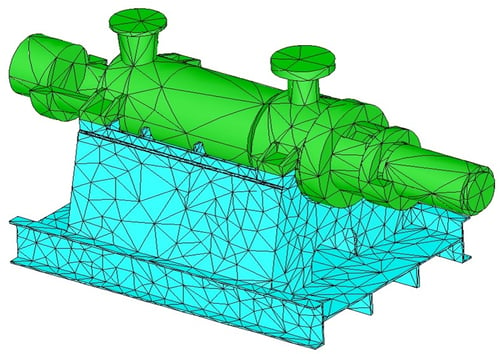

FEA model constructed to confirm the solution and to avoid costly and time-consuming trial and error problem-solving.

FEA model constructed to confirm the solution and to avoid costly and time-consuming trial and error problem-solving.

FEA results show a pump natural frequency at 92.1 Hz with all bolted foot connections secure. This is an acceptable 16% separation margin from running speed so is not resonant.

FEA model with the simulated “soft foot” on the one outboard foot predicts that the natural frequency drop to 77.8Hz which is a reasonable match to the test data (76.2Hz). The resultant separation margin of about -5% between running speed and the lightly damped natural frequency created the observed resonance problem.

Water Purification Plant Pre-Construction Specialized Vibration Testing for Future Improvements

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.