Resonance – Small Bore Pipe Vibration at a Pumping Station

This case study looks at a nagging high frequency problem within the pipeline industry - small bore piping resonance.

Small Pipe Pipeline Pumping Station High Frequency Resonance: Pipeline pumping stations are the heart of the oil & gas infrastructure, moving product throughout the country. However, they are not without their rotating machinery vibration challenges. This natural gas liquids (NGL) pipeline pumping station consisted of three pumps, and was experiencing high vibration (1 to 6 in/s) on many small bore piping (SBP or Small Pipe) vents throughout the process, both on the pumps themselves and the above-ground portions of the discharge and suction lines.

The pumps were 5-stage, variable frequency driven pumps, ranging from 1800-3600 rpm (30-60 Hz). Stages 1 and 2 had 6 vanes, with a vane pass frequency from 180-360 Hz. Stages 3, 4 and 5 had 7 vanes, with a vane pass frequency from 210-420 Hz.

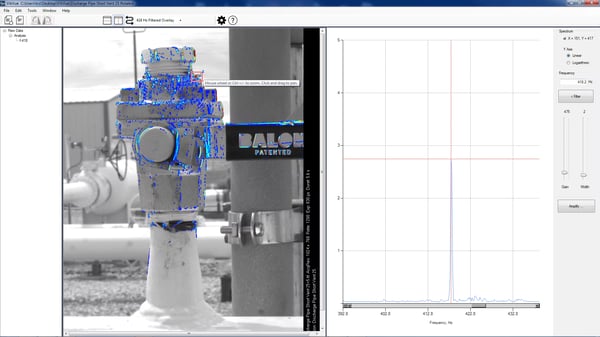

Utilizing VibVue®, it was straightforward to observe that the small pipe vent ports’ vibration had a strong frequency component at 418 Hz, which was a result of the natural frequency of the vent port being excited by the vane pass frequency of the pumps.

This frequency component was then significantly magnified to observe the mode shape of the vent ports.

Further analysis to determine how to precisely shift the natural frequency of the many vent ports is required to provide a full remedy, but VibVue® quickly and definitively demonstrated the nature of the problem.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Wastewater Treatment Blower High Frequency Audible Tone

A small, constant speed blower was emitting an uncharacteristically loud (120dB) audible frequency during operation.