Dramatic Ring-Section Pump Vibration Improvement Using ODS

MSI's ODS testing suggested modifications for the baseplate of a Boiler Feed Pump that greatly reduced the max vibration amplitude at the outboard bearing housing, solving the problem.

- Detected high vibration at the outboard bearing housing in the horizontal direction.

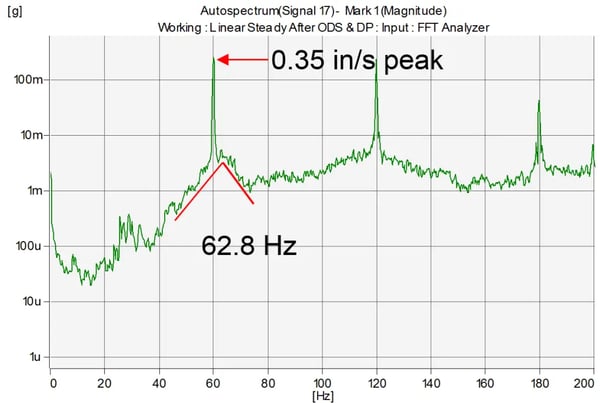

- Gradual vibration increment over time (from 0.06 in/s pk to 0.35 in/s pk).

- Over one year period, modifications recommended by preceding consultants were implemented to try and improve the erratic vibration amplitude, without success.

- Vibration Monitoring consisted of:

- Monitoring test during transient and steady operation to monitor the vibration amplitude, natural frequencies, and phase angle.

- Experimental Modal Analysis (EMA) test to determine the natural frequencies of the pump structure and the rotor system.

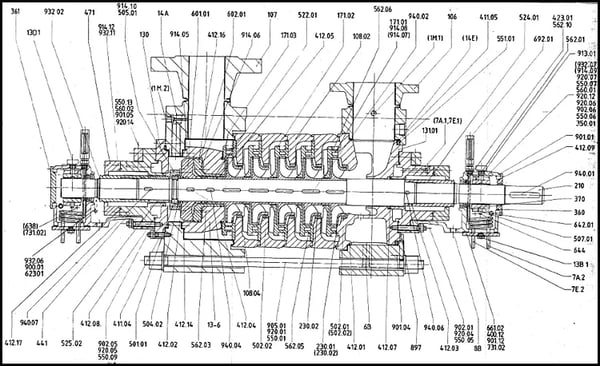

Cross-Section of Ring Section Boiler Feedwater Pump.

Learn About VibVue® Version 4.0

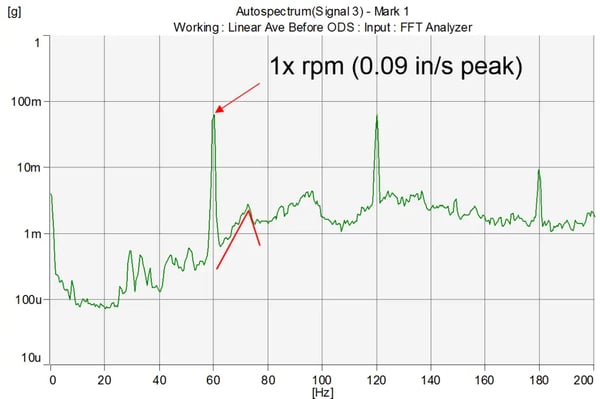

FFT plot of an accelerometer mounted to the outboard bearing housing before modifications.

FFT plot of an accelerometer mounted to the outboard bearing housing before modifications.

Boiler Feed Pump baseplate before modifications.

The root cause was excessive flexibility at the baseplate due to softness/ delamination of the internal grout. This phenomenon originated due to the looseness of the anchor J-bolts. After all suggested modifications were performed on the baseplate, the maximum vibration amplitude at the OBB housing in the horizontal direction was greatly reduced.

Boiler Feed Pump baseplate with modifications.

FFT plot of an accelerometer mounted to the outboard bearing housing after modifications.

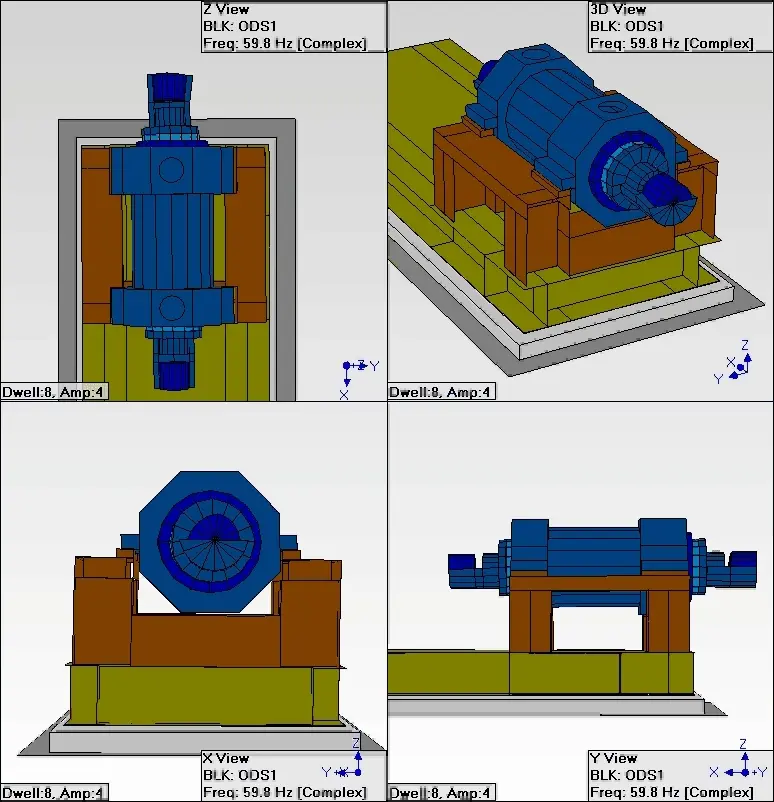

Click to view ODS animation showing soft foot between the baseplate and grout. The separation can be seen in the +y corner near the outboard bearing (top right and bottom left quadrants).

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.