Design Optimization Of A Low Pressure Steam Turbine Stage

- Challenge: Improve the performance of a low pressure (LP) steam turbine stage, preserving original rotor count and hub design.

- Results: Two percent gain in turbine performance.

- Impact: Increased efficiency delivers more power for same steam rate.

The low pressure end of a multi-stage steam turbine presents many technical challenges. Developing high efficiency blading that is acceptable both aerodynamically and mechanically requires integrated design and analysis.

A turbine end-user wanted to optimize the performance of one of his turbines, and submitted the last stage of his steam turbine for analysis and optimization. The stage was analyzed using Simcenter STAR-CCM+ CFD software which employed real gas properties in order to correctly model the thermodynamic properties of steam.

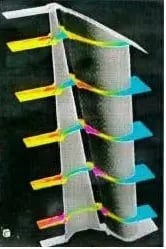

Figure 1. Original Design.

A compound-leaned stator design was developed to replace the original stator. This new design reduced transonic losses and provided improved loading from hub to shroud. Using ANSYS FEA software and CFX CFD software a new rotor was also designed and optimized aerodynamically as well as mechanically.

Figure 2. Redesign.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.