Design Of Oil Extraction Gear Pump & Motor

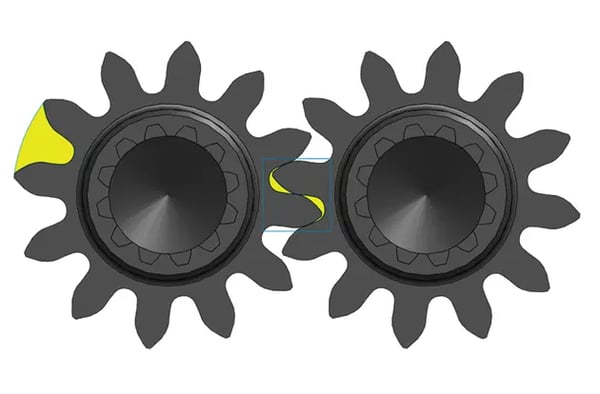

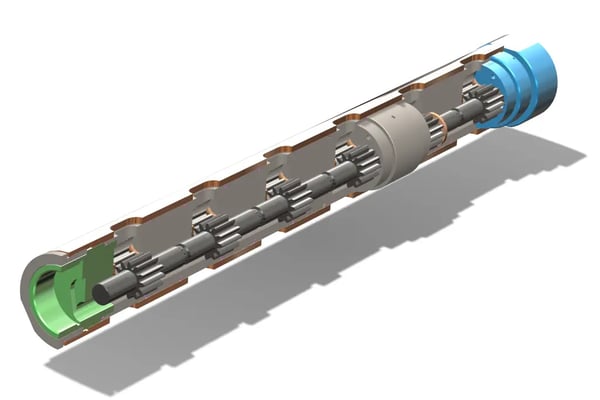

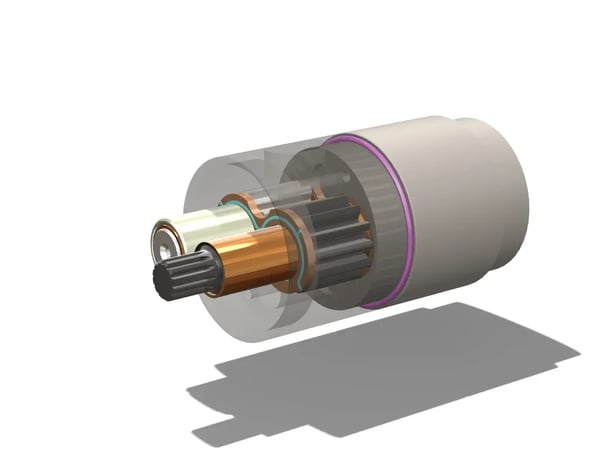

MSI was contracted to design a down-hole, multi-set external gear hydraulic motor – pump unit. The system had to meet specific requirements to achieve a design to replace the current pitot jet-pump configuration. Some of the design challenges included a small unit size, maximizing volume displacement, improving efficiency, and increasing durability under the extreme conditions of the well environment. Numerous iterations took place in both design and finite element analysis to achieve an optimal concept. A new gear profile (an involute-cycloid hybrid) was researched and developed to achieve the best possible volumetric displacement and tooth strength over standard gear profiles.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.