Curing Resonance In Reactor Feed Pumps

A newly constructed European nuclear power plant had all of its main feed pumps exhibiting vibration on the bearing housings in excess of the vibration specifications, by up to a factor of three, depending upon operating load. Nearly all of the vibration was at vane passing frequency. It was believed by the plant and the OEM that a shaft critical speed was at fault, possibly aided by excess vane/volute “B-gap” hydraulic forces which could only be reduced by giving up about half a point of efficiency, worth about 1 million dollars per year in increased operational costs and lost peak production opportunity. Testing showed that the rotor natural frequencies were nearly critically damped at all operating conditions, and was not the problem. B-gap forces were able to be “backed out” of the vibration signal once the rotor’s transfer function was determined by TAP™ impact modal testing, and were found to be in an acceptable range.

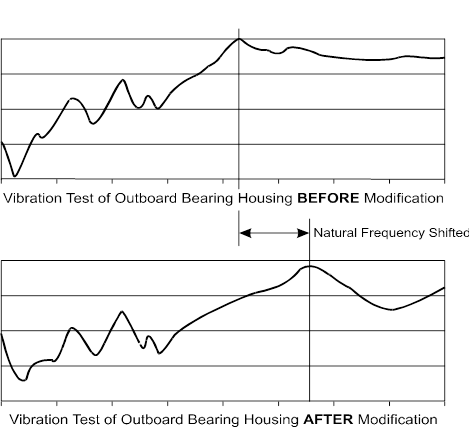

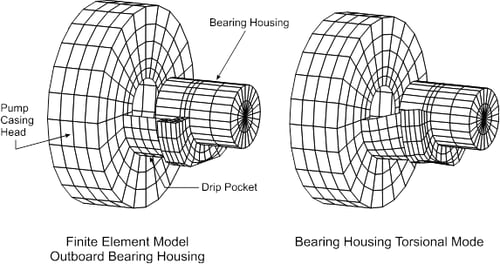

Instead of rotor critical speed or excess hydraulic load, testing proved that a complicated bearing housing resonance was the culprit. The mode shape movement involved combined horizontal bending and twisting of the housing through the 180 degree “drip pocket” that connected it to the casing. Its frequency shifted down during operation because of mass-loading of the housing by the shaft assembly when operation caused the bearing film to become stiff, which is why the OEM had not discovered the problem by stationary impact testing, as opposed to MSI’s TAP™ testing, which can be performed while the pump is operating. The bearing housing natural frequency was also confirmed by a finite element model that included the “drip pocket” attached to the pump body. A bolt-on “bridge” was designed to span the top of the drip pocket, such that the torsional part of the motion was discouraged, shifting the natural frequency out of the range of the vane pass frequency. Peak vibration dropped to within specification, and this problem was removed as an obstacle to the plant commissioning, which was only several weeks away. A delay in plant commissioning would have cost about $1/2 million per day.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.