Design And Test Of An Axial Hydro Turbine

MSI Engineers Designed and Tested an Optimized Renewable Energy Machine

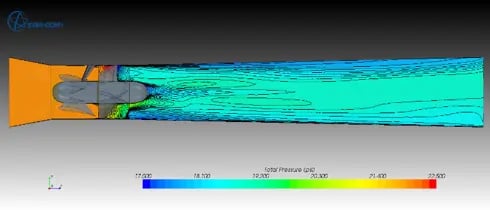

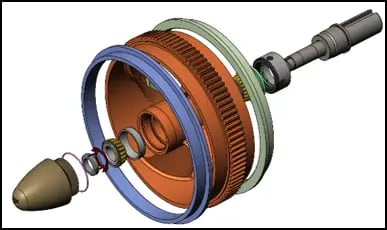

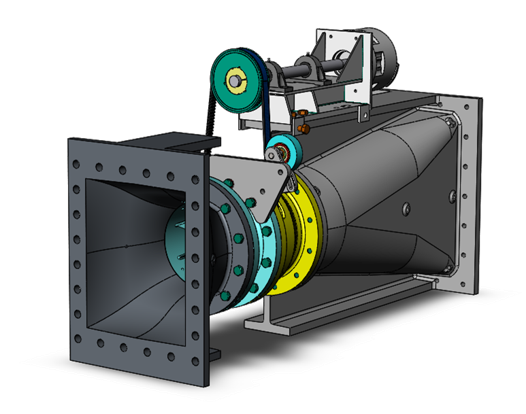

MSI was tasked with designing a subscale (1/6th ) axial hydro-turbine utilizing a belt system to drive a generator. The turbine rotor consisted of a CNC machined wheel with teeth machined on the shroud to utilize an industrial belt for transmitting power. A full turbine system from inlet to draft tube was designed and tested in Massachusetts.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.