Assess Water Level Effects On 5-Stage Vertical Turbine Pumps (VTP)

Pump Engineers Need to Accurately Predict Structural Natural Frequencies of a Pump System by Including the Water Level

Vibration On Vertical Turbine Pumps (VTP): MSI pump engineers were commissioned by a pump OEM to perform a finite element analysis (FEA) of a future pump assembly to predict the structural natural frequencies of 5-stage vertical turbine pump (VTP) system. By taking a system-level approach and performing the analysis at both the high water level (HWL) and low water level (LWL) station conditions, MSI was able to predict a potential resonance problem with the 2nd below-ground pump bending mode within the 1x pump RPM range at the LWL condition. The pump manufacturer was then able to make design changes before building the pump to avoid installing potential resonance and vibration issues.

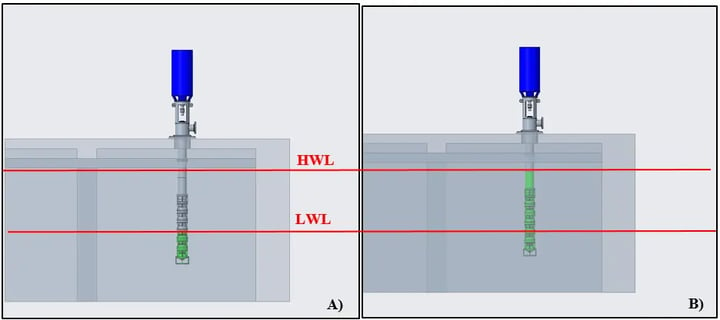

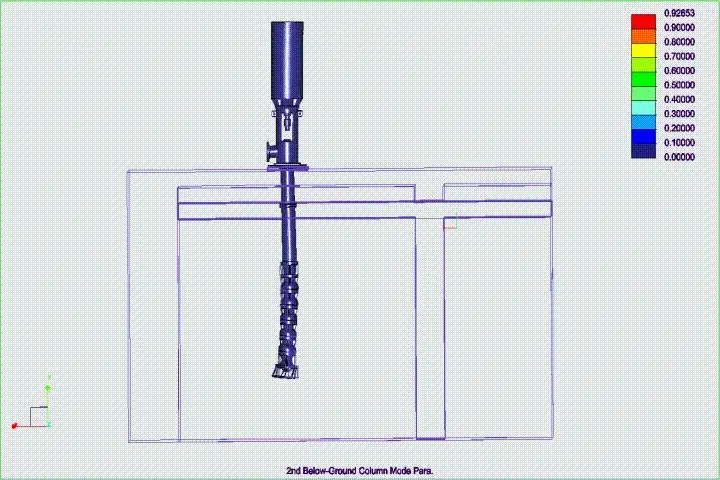

Based on MSI engineers' FEA models of the full pump assembly, including the pump, motor, stiffness from the piping, and station foundation, modeled in full 3D as shown in the image below, it was predicted that the pump structural natural frequencies would all be greater than ±20% from the 1x pump running speed range in the LWL conditions, as shown in the table. However, when considering the internal and swept water effects of the same pump at the HWL conditions, the 2nd below-ground bending mode of the column was predicted to be only 13.2% from the 1x pump running speed range which violated the separation margin requirements of the specification, as well as the recommended Hydraulic Institute separation margins of ±15%. A plot of the potentially problematic 2nd below-ground bending mode shape is shown in the animation. MSI was able to communicate this potential vibration issue to the pump OEM before the pump was built so that design changes could be made to avoid installing vibration problems.

The following images show models of the 5-stage vertical turbine pump assembly evaluated at LWL conditions, as shown in A, and at HWL conditions, as shown in B. Volumes shown in green indicated submerged pump components.

The following table lists of modes and separation margins for the structural modal analysis of the 5-stage vertical turbine pump assembly at the low water level (LWL) and high water level (HWL) conditions.

| 5-Stage Vertical Pump Structural Modes: Assessment of Water Level Effects | ||||||

| Pump Speed (RPM): 1240-1755 | ||||||

| Description | Low Water Level: Baseline FEA Predicted Natural Frequency | Separation Margin from 1x Pump (20.7-29.6 Hz) | High Water Leve: Baseline FEA Predicted Natural Frequency | Separation Margin from 1x Pump (20.7-29.6 Hz) | ||

| Hz | CPM | % | Hz | CPM | % | |

| 1st Below-Ground Column Mode Parallel | 6.93 | 416 | -66.5 | 6.63 | 398 | -68.0 |

| 1st Below-Ground Column Mode Perpendicular | 6.95 | 417 | -66.4 | 6.65 | 399 | -67.9 |

| Motor Rocking Mode Perpendicular | 13.7 | 822 | -33.8 | 13.7 | 822 | -33.8 |

| Motor Rocking Mode Parallel | 14.1 | 846 | -31.9 | 14.1 | 846 | -31.9 |

| 2nd Below-Ground Column Mode Parallel | 36.5 | 2,190 | 23.3 | 33.5 | 2,010 | 13.2 |

| 2nd Below-Ground Column Mode Perpendicular | 37.4 | 2,244 | 26.4 | 34.3 | 2,058 | 15.9 |

As you can see, a LWL analysis indicated adequate separation margin between the all modes considered, but the HWL analysis indicated potential issues with the 2nd below-ground column mode for the pump.

The LWL analysis indicated negligible forced response at 33.5 Hz, which was the 2nd Below-Ground Column Model Parallel for the HWL analysis.

2nd Below-Ground Column Mode is not evident at 33.5 Hz using Low Water Level analysis

2nd Below-Ground Column Mode response at 33.5 Hz is evident with High Water Level analysis

2nd Below-Ground Column Mode response at 33.5 Hz is evident with High Water Level analysis

Check out these related case studies to see how the foundation and suction/discharge piping affect your pre-installation design assessment analysis as well.

If you would like to discuss pre-installation design assessment analysis for pump or other rotating machinery project with an experienced MSI Engineer, Contact Us.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.