Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing pipeline company screw pump problems. Field tests were conducted to diagnose the cause and propose a solution to the problem of the pipeline pump.

- Problem Statement (Challenge)

- What (type of machine): Pipeline Screw Pump

- Where (State/ Country): Louisiana

- Why (problem/reason): Determine the root cause of excessive piping, pump vibration, previous internal pump wear, and recommend solutions.

- Work Performed

- Results/ Solution

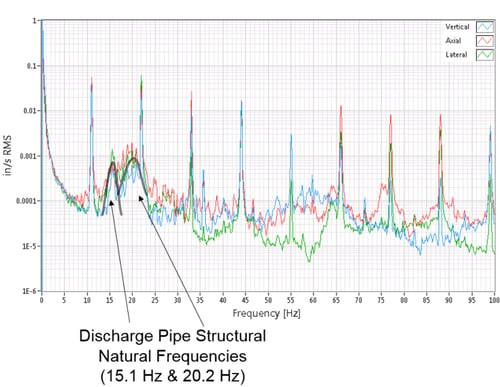

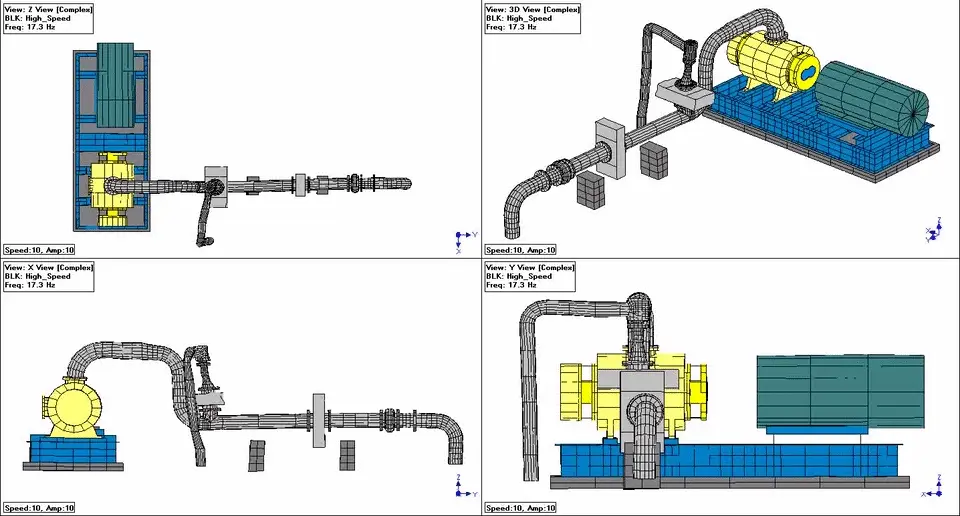

- Findings: Piping natural frequencies shift into strong resonance at times. Pump twist modes go into resonance due to a lack of stiffness in the baseplate, driven by piping motion.

- Impact: Piping structural supports were recommended to increase the separation margin from excitation sources. Grouting the baseplate was recommended to increase system damping and to shift the natural frequencies away from the running speed excitation.

FFT plot from an accelerometer located on the discharge pipe.

Operating Deflection Shape at 17.3 Hz

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.