Resolving A Sewage Pump Problem Via Specialized Testing And Analysis

Based on MSI’s thorough testing, which included Experimental Modal Analysis (EMA), Operating Deflection Shape (ODS), and dynamic pressure testing, the problem root cause was determined to be a combination of the following factors: operation of the pumps away from the BEP (hydraulic issues), excessive pressure pulsations generated in the suction line due to low suction pressure and low flow capacity (suction recirculation), excessive flexibility of the pump volute causing “breathing” motion under pressure pulsations, and weakness of the motor support/ pump casing (structural natural frequencies close to or within 1x rpm and vane pass frequency range).

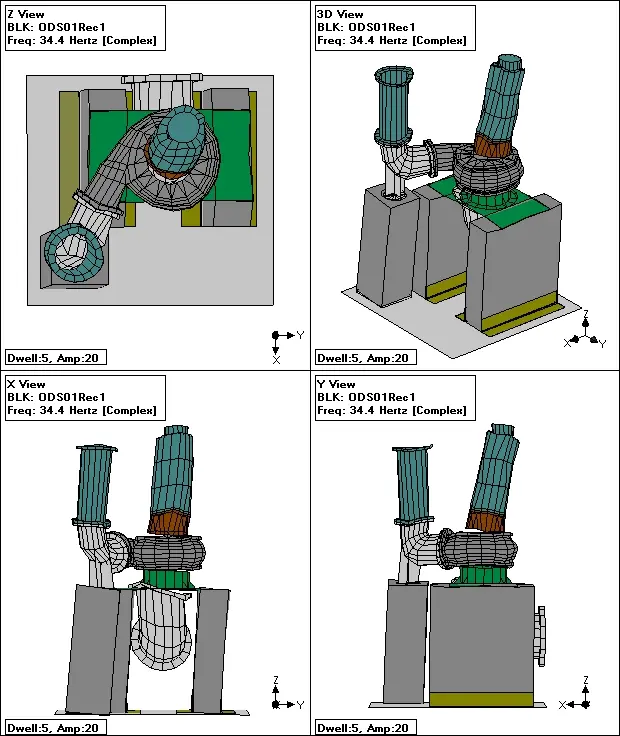

Figure 1. Properly performed, a detailed ODS is worth a thousand pictures in helping to understand and explain a system dynamics problem. Motion is exaggerated but to scale.

Figure 1 is an example Operating Deflection Shape (ODS) animation from a recent specialized testing project MSI performed on behalf of an engineering firm for newly installed close coupled vertically oriented sewage pumps.

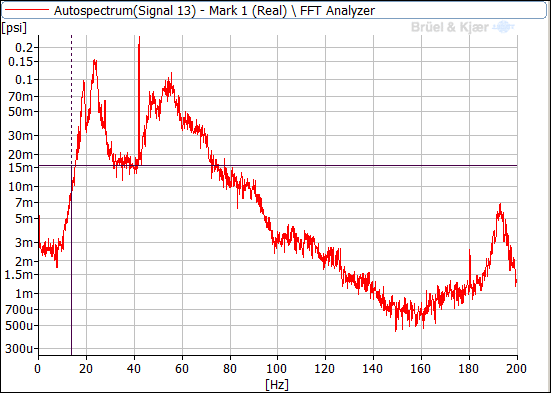

In addition, acoustic natural frequencies near 1x rpm and vane pass frequency were present along with a soft-foot between the concrete pier and the floor (Pump #2 and Pump #4). Dynamic pressure transducers were used to measure the instantaneous pressure pulsations and their frequencies so their excitation impact could be quantified (Figure 2).

Figure 2. Example FFT plot of pressure pulsation measurements using dynamic pressure transducers. This process is used to determine the frequency and magnitude of the suction or discharge flow pressure. Pressure pulsations, particularly at off-design flow conditions, can excite normally benign system natural frequencies.

The ODS animation depicted in Figure 1 shows mostly a rocking motion of the motor in the perpendicular direction to the discharge pipe. In this example, this 34.4 Hz complex mode is being excited by vane pass frequency. In addition, a strong “breathing type” motion of the pump casing (volute) was detected, while the motor structure and support rock as a rigid body (pivoting on the volute casing). Other lower order modes were also being excited.

Based on the test results, MSI recommended shifting the offending natural frequencies to avoid a resonance condition. Rather than attempt trial and error gusseting, MSI designed and analyzed a practical and appropriate arrangement to detune the system. The “as is” finite element analysis (FEA) model was initially calibrated using the ODS and impact test results to reduce risks. Additionally, corrective actions for a soft foot and wet well level issues identified by the testing process were provided. Solutions designed and analyzed by MSI were successfully implemented to resolve the problem without resorting to more traditional trial and error problem solving.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.