Automated Design Optimization Of A Hydroturbine

Achieving an Optimized Performance using a Parametric Design Study for 25 Geometry Variations in less than 24 hours

A 1,000kW hydroturbine was optimized by applying automated Design Space Exploration with minimal user interaction, resulting in a design with improved efficiency and power output.

The objective was to find improved performance within an existing casing by varying wicket gate and runner blade design at current conditions (namely pressure differential). A total of 25 design variations were generated within the turbomachinery design software CFturbo. The batch output from CFturbo was fed seamlessly into an automated study within the Design Manager in computational fluid dynamics analysis software STAR-CCM+.

Zoomed in view of the wicket gate and runner geometry/orientation for all 25 design variations

The computational study for all designs was completed automatically without user intervention on MSI's high-performance computing cluster in less than 24 hours of runtime. The outputs of the analysis were compiled and compared, demonstrating clear design advantages for improved efficiency and power output.

Design Variables and Results Table, Baseline Design is Design 13

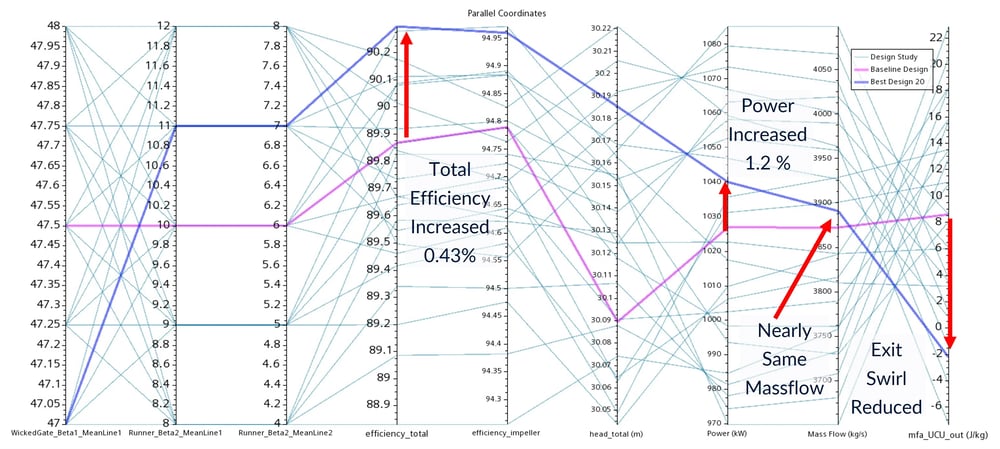

Results in Parallel Plot, Each Line Representing Individual Candidate Design - Best Design (blue) Resulted in Net Gains of Efficiency and Power Output with Approximately Same Massflow and Reduced Exit Swirl

Results in Parallel Plot, Each Line Representing Individual Candidate Design - Best Design (blue) Resulted in Net Gains of Efficiency and Power Output with Approximately Same Massflow and Reduced Exit Swirl

The results of the study concluded:

- Eight designs yielded improved efficiency, with the best being Design 20

- Improved power and efficiency achieved at the same mass flow as the original design

- Improved exit swirl

- Twenty-five designs analyzed automatically, with runtime less than 24 hours

For an in-depth webinar on how the design and analysis tools were integrated for this example, click the button below.

To learn more about our Computational Fluid Dynamics Analysis or Turbomachinery Development capabilities, or to get access to the software tools we use to do the things we do, Contact Us.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Rerate of a Francis Hydro Turbine

MSI was tasked with optimizing a 1920s Francis style hydro-turbine runner.

Case Study

Reconciling Predicted Results to Test Stand

Test stand data vs. predicted performance.

Case Study

Analysis of Multiple Hydro Turbines in a Parallel Array

Modeling and analysis of parallel hydro turbines.