Acceptance Criteria For Your Sump Pump With Our Optimized Inlet Piping Designs

Pumps are often in awkward places with limited space available to design long straight inlet pipes. Bends and Valves upstream can disturb the flow which can significantly compromise pump performance and reliability.

Our Fluids Engineering Team help our customers to develop flow optimizations in the tightest of spaces to meet industry standard acceptance criteria (i.e. Hydraulic Institute Standard) saving our customers costly prototyping and lengthy field tests. In this study MSI's team uses mainly readily available components to reconfigure the piping inlet on a 3500 GPM pump for a municipal pumping station for easy implementation and install. State-of-the-art High-Fidelity transient CFD analysis in STAR-CCM+ on MSI's computer clusters were utilized to guarantee that ALL acceptance criteria were exceeded. Specifically the transient simulation enables exact analysis of time averaged flow metrics just like data would be recorded in a physical model test.

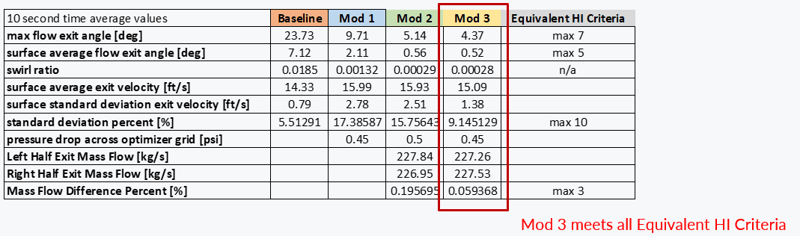

Results Metrics Overview for All Designs

The table above shows results from the Optimization Study. The CFD results are time averaged values at the pump inlet flange (pipe exit) over 10 seconds with a timestep of 0.02s. The Baseline is the existing design installed in the field and violates the HI Acceptance criteria. The Design Modification 3 meets all criteria and has been chosen to be implemented by the customer.

Contact us for your pump inlet optimization problem and we will find a solution for you.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Rerate of a Francis Hydro Turbine

MSI was tasked with optimizing a 1920s Francis style hydro-turbine runner.

Case Study

Reconciling Predicted Results to Test Stand

Test stand data vs. predicted performance.

Case Study

Analysis of Multiple Hydro Turbines in a Parallel Array

Modeling and analysis of parallel hydro turbines.