Root Cause Analysis (RCA) of Pump Rotor Failures

Three strikes...

This particular hydrocarbon cracking pump had failed three times, and was critical to a diesel fuel production process at a major California refinery. Each failure closed down or severely curtailed fuel production at the refinery, at an average cost of about $750,000 per day.

Diagnosing the Pump Problem

MSI's root cause analysis (RCA) included pump vibration testing to determine the shaft critical speeds while the pump was operating at various loads and with various product densities and viscosities. This allowed a rotordynamics analysis of the 11 stage flexible shaft pump to be calibrated by the test results, so that the analysis could then be used to accurately predict why certain operations in the process might have caused pump failure, and whether proposed rotor changes would avoid future problems.

Rotor Vibration Spectrum

|

"...the main reason for past failures was a poorly damped backward processional rotordynamic critical speed...excited operationally at 2X running speed...due to a rub of the balance piston." |

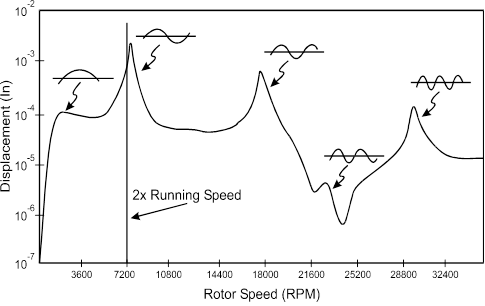

The pump vibration testing & troubleshooting found the critical speeds of the operating pump, and the combined testing and analysis showed that the main reason for past failures was a poorly damped backward processional rotordynamic critical speed, which was located at a lower speed than expected. The critical speed would be excited operationally at 2X running speed, which rotordynamic analysis strongly suggested was due to a rub of the balance piston.

Pump flow path hydraulic analysis demonstrated that this was facilitated when pumping hydrocarbon product with excessively low specific gravity, because of flashing of the liquid at the exit of the balance drum causing loss of a liquid film between the rotor and stator.

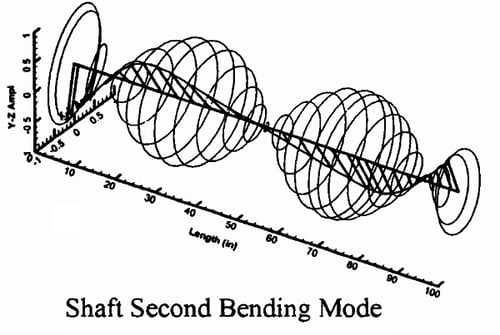

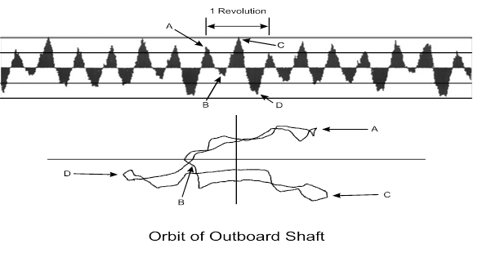

MSI's Time-Averaged Pulse (TAP™) test performed by MSI engineers clearly showed that the rotor's second natural frequency (“second bending” mode) was near 2X running speed, and proximity probe traces showed that the orbit was made up of primarily 2X running speed vibration during times when the pump experienced the operational difficulties.

The Fix

The pump rotor design was changed by modifying the wear ring seals to make this mode more difficult to excite, and the minimum permitted specific gravity was increased by the plant to a level that would avoid flashing. The pump, which had been failing roughly every three months, has now run for many years without further difficulty.

Read About: "Wastewater Treatment Blower High Frequency Audible Tone"

Read About: "Wastewater Treatment Blower High Frequency Audible Tone"

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Troubleshooting a Pipeline Renewable Diesel Screw Pump

Elevated vibration levels were causing a pipeline company screw pump problems.

Case Study

Petrochemical Ammonia Recip Compressor Piping Troubleshooting

Excessive motion by the discharge piping of a petrochemical ammonia reciprocating compressor startled the operators.

Case Study

Oil Tanker Pumping Station Screw Pump Troubleshooting

Troubleshooting a new oil tanker pumping station in Colombia consisting of 4 screw pumps. Specialized testing revealed that piping natural frequencies were to blame.