Aeroderivative Gas Turbine Modifications Solve a Problem

MSI Troubleshooting Engineers Determine Resonance is Causing Chronic Turbomachinery Vibration Problems, and Provide an Engineered Solution.

Gas Turbine Vibration: MSI engineering consultants were contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator. The gas turbine vibration levels were detected to be as high as 1.75 in/s peak at 1x HP rotor running speed measured on the turbine's HP compressor had been reported at full load. Historically, the installation had a series of failures such as cracking at various locations, rubbing of the rotor on the front case, and a catastrophic failure of the compressor rear frame.

Modal analysis animation at 169.3 Hz

MSI engineers performed a series of specialized field troubleshooting tests to characterize the gas turbine problem, and performed very detailed 3-D finite element analysis (FEA) to design an interim solution. MSI’s temporary solution was used to draw the OEM’s attention to the problem and led to their agreement to modify the original design.

|

The bell modes of the gas turbine's HP compressor casing and the combustor casing/ compressor rear frame (CRF) were discovered to be tuning into the major excitation source of 1x rpm of the HP rotor |

Time Averaged Pulse (TAP™) Modal Analysis testing was used to determine the bell modes of the gas turbine's HP compressor casing and the combustor casing/ compressor rear frame (CRF), which were discovered to be tuning into the major excitation source of 1x rpm of the HP rotor. The resonant bell mode produced casing vibration levels high enough to result in casing HCF fatigue cracking. The video above is a modal animation showing one of the resonant mode shapes: bucking motion bell mode of the HP compressor casing. This mode combined with plate modes of the front end support plate and the longitudinal beams of the baseplate.

Strain gage data was used to determine effects of loading on the power turbine mounting supports and the compressor frame mounting supports. Most of the strain gage readings exhibited confusing nonlinear behavior due to mechanical strain combining with thermal growth of the legs. The torque reaction bar measurements were contaminated by unreacted pressure load from the power turbine nozzle. MSI identified and sorted out these effects to effectively troubleshoot the problem.

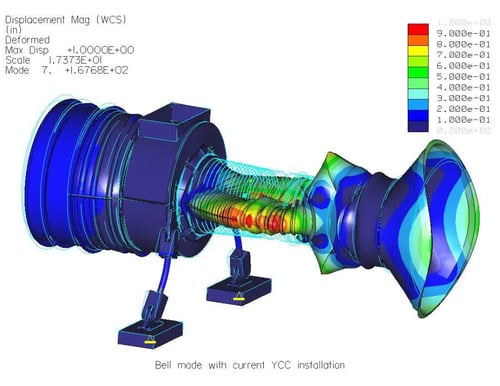

FEA Modal Analysis Results at 167.6 Hz

Due to the nature of the vibration root cause, which MSI’s testing demonstrated was resonance of the bell mode, MSI engineers recommended a modification of the gas generator casing. A 3-D FEA model was constructed and calibrated as an “as built” analysis using test results by MSI. Proposed modifications were evaluated and refined via FEA, such as redesigning the flange attachment between the HP compressor and the LP compressor, as well as the LP turbine and PT, to modify the edge conditions of the casing to tune it as a “bell” in order to efficiently shift the problem natural frequencies. Stiffening of the front/ center baseplate and turbine exhaust nozzle was found to also adequately shift the modes, but with less margin. An innovative solution involving a high temperature damping ring surrounding the casing was also proposed, which eliminated the need for other turbine modifications. The customer selected the fix that best met their needs, and the long-standing problem was solved with a successful interim fix.

Due to the nature of the vibration root cause, which MSI’s testing demonstrated was resonance of the bell mode, MSI engineers recommended a modification of the gas generator casing. A 3-D FEA model was constructed and calibrated as an “as built” analysis using test results by MSI. Proposed modifications were evaluated and refined via FEA, such as redesigning the flange attachment between the HP compressor and the LP compressor, as well as the LP turbine and PT, to modify the edge conditions of the casing to tune it as a “bell” in order to efficiently shift the problem natural frequencies. Stiffening of the front/ center baseplate and turbine exhaust nozzle was found to also adequately shift the modes, but with less margin. An innovative solution involving a high temperature damping ring surrounding the casing was also proposed, which eliminated the need for other turbine modifications. The customer selected the fix that best met their needs, and the long-standing problem was solved with a successful interim fix.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

A Cure for the Common Cold – in Turbines

A steam turbine at a waste-to-energy facility in the Northeast underwent a scheduled repair, at which time the turbine bearings were reworked, after which the turbine periodically experienced very high amplitude shaft vibrations.

Case Study

BFP Fluid Drive Troubleshooting

A boiler feed pump (BFP) driven off of the main steam turbine via a fluid drive was experiencing high vibration levels leading to frequent replacement of the fluid drive bearings.

Case Study

Aeroderivative Gas Turbine Modifications to Solve a Problem

MSI was contracted to understand and help solve a high vibration problem on an aero-derivative gas turbine driven generator.