Reciprocating Pump Torsional Analysis For End User

Reciprocating Pump Torsional Analysis for End User

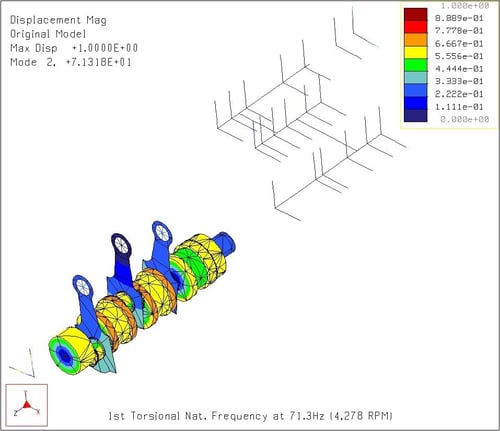

MSI engineers performed torsional analysis of a reciprocating pump/ gear/ motor system being designed for a large overseas petroleum drilling venture. Analysis of the initially designed system indicated that there was a possibility of resonant torsional vibration, driven by 50 Hz line frequency. The customer requested that additional analysis be performed to investigate how coupling options could be modified to provide improved factor of safety relative to the occurrence of torsional resonance. It was discovered that, by switching the pump coupling to a double engagement gear coupling from a flexible spring element coupling, the original problem was fixed, but a new resonance problem was created at twice line frequency. By lengthening the coupling hubs on each side to the maximum standard length, a factor of safety of over 15 percent was obtained relative to the closest torsional resonance, consistent with good engineering practice. The manufacturer of the system included the recommended design change, and the pump was placed in service, functioning with no vibration or reliability problems.

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Solids Handling Pump Repetitive Failure of Bearing and Seal

An engineering construction firm needed help in determining the root cause for the repetitive pump bearing and seal failures of a solids handling pump and to provide a solution to eliminate the issue.

Case Study

Design Assessment Mitigates Risk

A design assessment was carried out in an effort to prevent potential premature bladed disk and impeller fatigue failures of three newly installed critical compressor trains.

Case Study

Development of a Prototype Vacuum Blower

A major aerospace equipment supplier/manufacturer needed to design and prototype an FAA-approved vacuum generator for use on commercial aircraft.