Sub-Synchronous Vibration In A Reverse Osmosis Membrane Vertical Turbine Pump

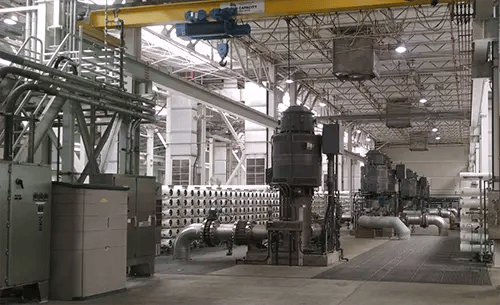

A construction firm needed help in determining the root cause for the high vibration amplitude of the above-ground structure on four out of six newly installed pumps and provide a solution to mitigate this issue. These new pumps were part of a plant expansion project to increase water capacity.

- Problem Statement (Challenge)

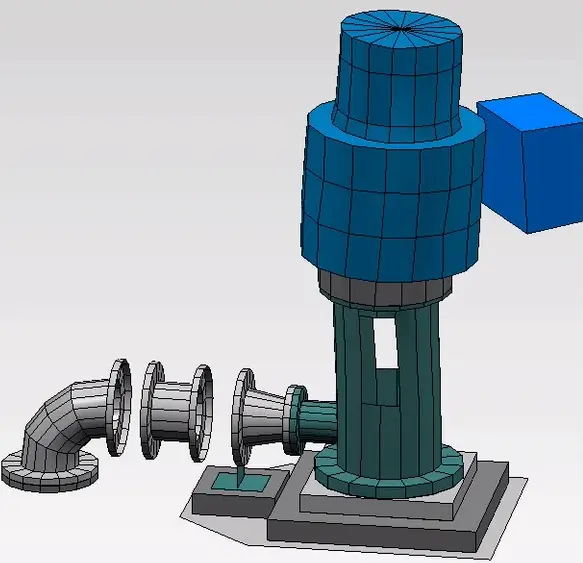

- What (type of machine): Reverse Osmosis Membrane Feed Vertical Turbine Pump

- Where (State/ Country): California

- Why (problem/reason): A construction firm needed help in determining the root cause for the high vibration amplitude of the above-ground structure on four out of six newly installed pumps and provide a solution to mitigate this issue. These new reverse osmosis membrane feed pumps were part of a plant expansion project to increase capacity. MSI was called to conduct specialized vibration testing on the pumps system and help avoid dealing with a delay penalty clause.

- Work Performed

- Results/ Solution

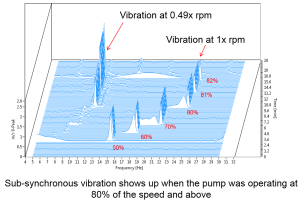

- Findings: The high vibration of the above-ground structure of the pumps is due to a structural resonance of a natural frequency (“trunion” mode, where the above-ground structure pivots in one direction and the below-ground structure swings in the opposite direction as a rigid body). This natural frequency is excited by a rotordynamic induced fluid whirl that is likely occurring in the pump bearings at a frequency from 44% to 49% of the running speed (sub-synchronous vibration or SSV). This SSV is caused by potential tight clearance between the pump shaft and the plain sleeve bearings.

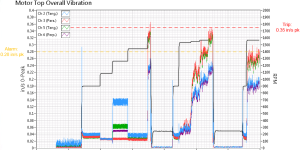

- Impact: The findings led MSI to recommend a change (increase) in the diametral clearance of the pump bearings which was predicted to eliminate the source of excitation force such that the “trunnion” would not be excited. In addition, the clearance of the motor sleeve bearings was to be investigated as well. The pumps having initially failed the HI/ANSI vibration specification caused both the OEM and construction firm to scramble to prevent having to deal with a project delay penalty clause, which was achieved with MSI.

Overall vibration trend plot at the top of the motor

Waterfall trend plot

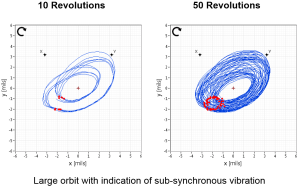

Pump shaft orbit plots showing sub-synchronous vibration which shows up as loop in loop

ODS animation at sub-synchronous frequency. ![]()

ODS animation at 1xN frequency

Read About: Wastewater Treatment Blower High Frequency Audible Tone

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

New Orleans Flood Control Pumping Stations Vibration Analysis

MSI was recommended to analyze flood control pumping station system dynamics, including evaluation of the platform design with regard to vibration.

Case Study

Water Treatment Plant Pumps Fail Vibration Specification During Commissioning

A contractor putting together a water treatment facility encountered vibration issues with various pumps during commissioning.

Case Study

Newly Installed Water Treatment Plant Pumps Cavitating & Vibrating

A county water treatment plant heard “cavitation-like noise” from their newly installed pumps and called MSI for help.

.webp?width=500&height=447&name=Sub%20Synchronous%20Vibration%20In%20A%20Reverse%20Osmosis%20Membrane%20Vertical%20Turbine%20Pump%20(2).webp)