Rerate Of A Francis Hydro Turbine

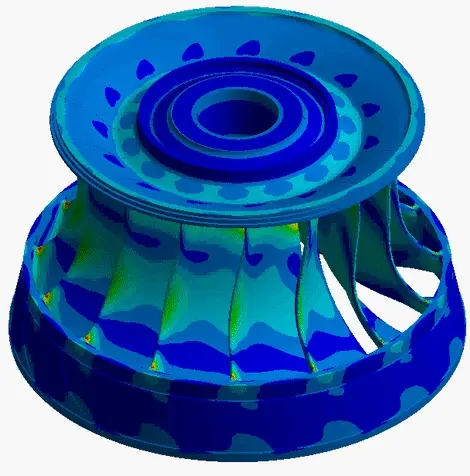

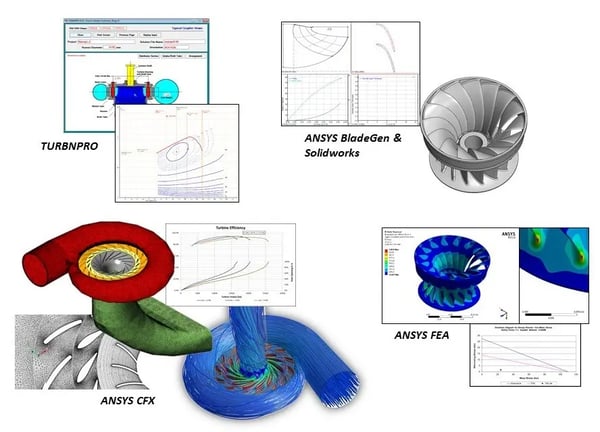

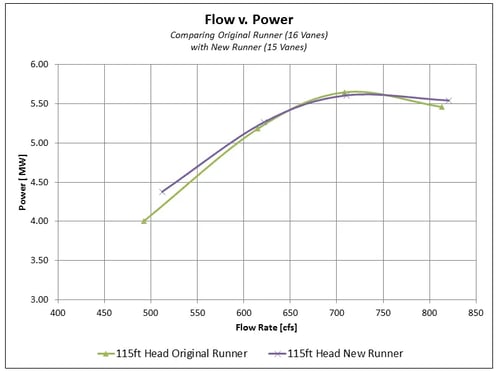

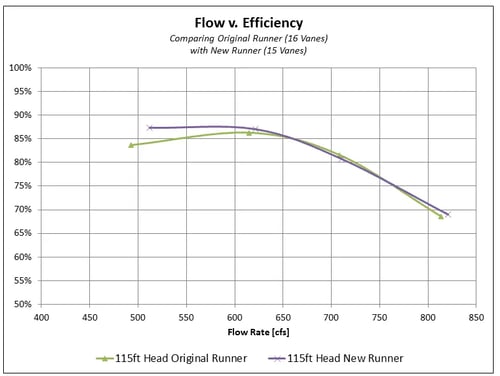

MSI was tasked with evaluating a 1920s Francis style hydro-turbine runner in order to replace the aging original ones at a plant near the Hudson River in Upstate NY. A new blade design improved runner efficiency as well as decreased the blade count from 16 to 15, reducing the runner weight. The runner was later cast from CF3 Stainless Steel and required geometric evaluation of the agreement between the CAD and the final product. Using 3D laser scanning, a 3D point cloud was generated to overlay with the CAD model to determine any deviations. The casting was well within the tolerance of the design.

MSI's Hydroturbine Design Process

Analytical Comparison Curves Between Original Runner and New Runner with Improved Blade Geometry (Evaluated using ANSYS CFX)

REAL-WORLD EXAMPLES AND CASE STUDIES

MSI In Action

Case Study

Improving Cost of Ownership with Vibration Risk Reduction: 1/2

Focusing on vibration and dynamics issues during the plant design phase of a project pays off with smoother commissioning and lower cost of ownership over the plant’s life.

Case Study

Simulating the Performance of a Spinal Implant

A manufacturer of an innovative spinal implant approached MSI for help in assessing the implant’s structural integrity.

Case Study

Dynamic Analysis of a Street Sweeper for the Manufacturer

Troubleshoot and identify potential opportunities for early bearing failure, MSI performed experimental modal analysis (EMA) and operational deflection shape (ODS) tests on a prototype unit for the manufacturer.